Welcome to HeiQ - Heitkamp Kunststofftechnik

Consulting, Management and Technical Support for Thermoplastic Foam Moulding Projects (TFM-Projects)

Sale of High-Performance Tools for the

Thermoplastic Injection Moulding of Thin Wall Parts

Services, Consulting and Sales

Scope of Services

- Project management (TFM-Projects)

- Consulting on development activities (e.g. lightweight construction)

- Support in the acquisition and quotation phase

- Trainings and employee qualification

- Execution of workshops on the subject of TFM

- Process evaluation and optimization

- Sale of high-performance moulds for thin-wall parts

Qualification

Foaming Technologies

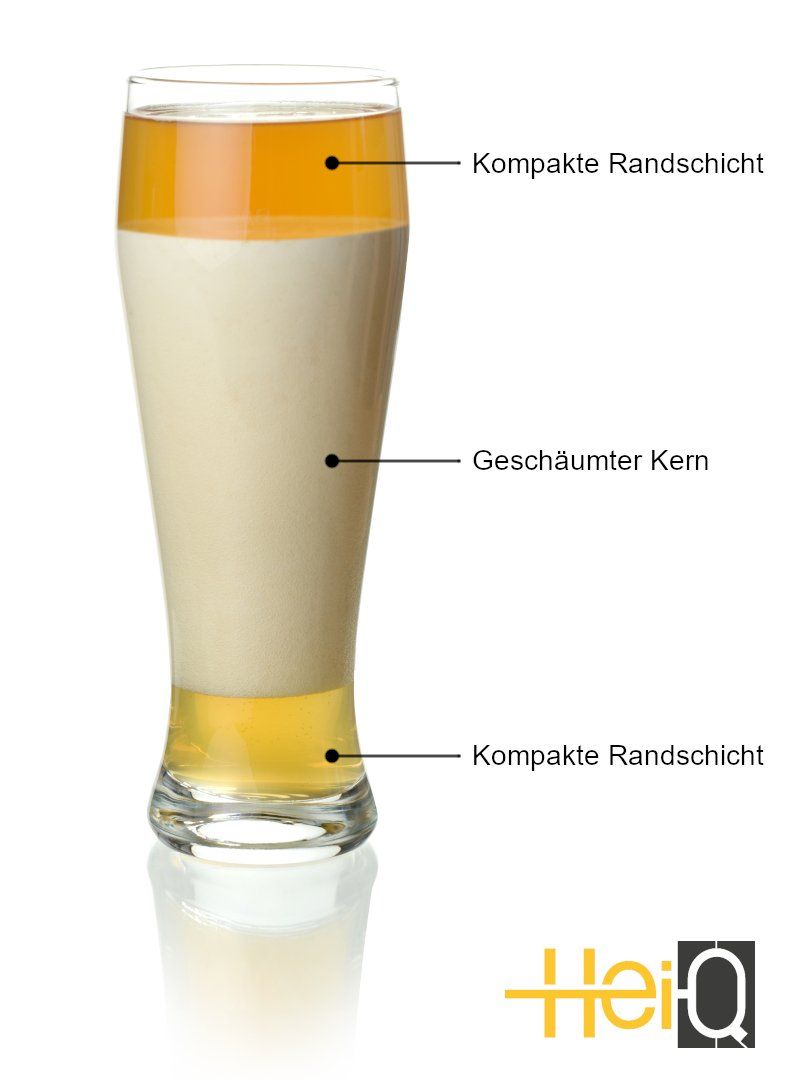

In order to describe the differences between the thermoplastic foam moulding technologies available on the market, the part production process should be divided into two main steps:

Step 1 is plasticizing the resin and adding or producing a gas (usually N2 or CO2) which causes an expansion force in the melt.

Step 2 consists of filling a mould (at injection moulding or blow moulding) with that gas-laden melt, which then foams up after suffering a pressure drop and forms out a cell structure in the plastic part.

Step 2 shows similar correlations for all TFM processes. The results for the cell structure and density of the selected resin are mainly influenced by the amount of gas dissolved in the melt and the selected filling parameters at the production machine.

The differences between the individual TFM solutions available are mainly found in step 1.

The first rough distinction is either physical or chemical foaming. While in the addition of chemical blowing agents (CBA's) the gas responsible for foaming is only released in the melt by friction and heat and by-products are produced, in the physical processes the gas is added directly to the resin under pressure.

The differences in the physical TFM technologies can be found in the respective hardware layout and at which place the gas responsible for foaming is added to the thermoplastic resin.

HeiQ offers the experience and objectivity to qualify and project the TFM technology suitable for the customer and the product.

High-Performance Moulds for Fast Cycle Times for Thin-Wall Injection Moulding Technology

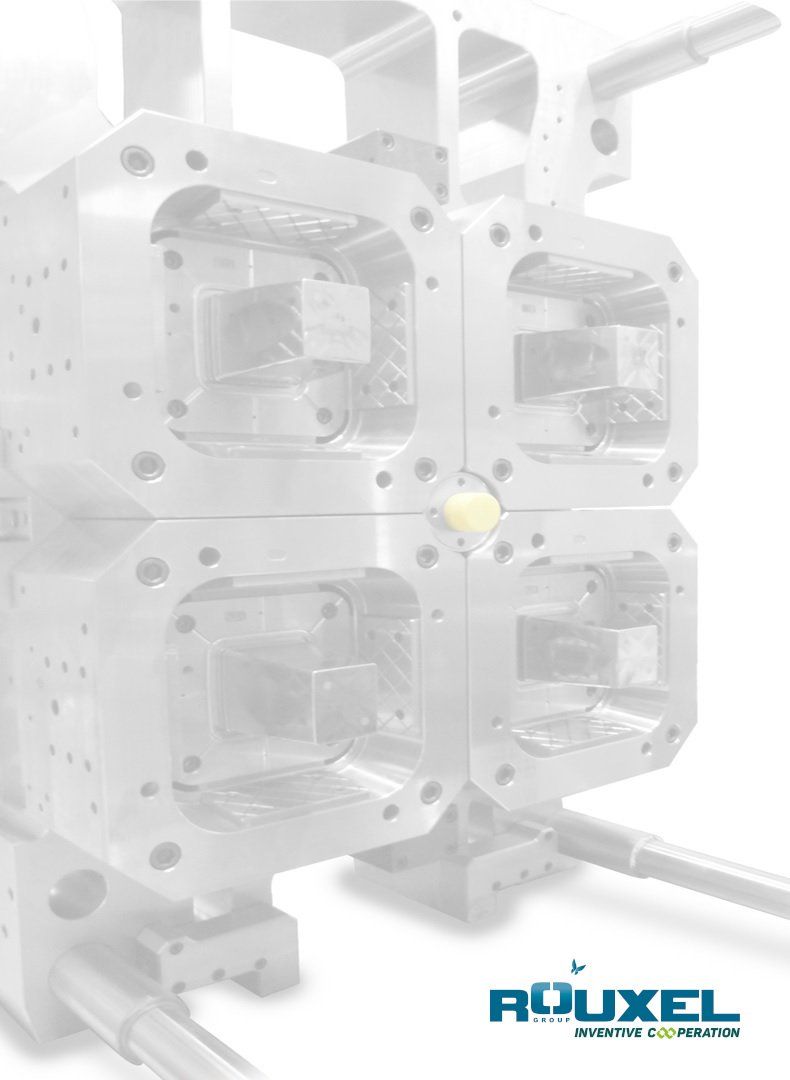

Since February 2022 HeiQ - Heitkamp Kunststofftechnik has become responsible for the sales of moulds for the plastics injection moulding production of high-volume packaging in the food, pharmaceutical, medical, cosmetics and horticultural sectors in Germany, The Netherlands and Denmark for Rouxel Mold in Saint Arnoult en Yvelines, France.

Rouxel Mold manufactures high-speed and multi-cavity moulds for thin-wall technology with high quality standards and long guarantee. The focus is on stack moulds with and without in-mould labelling (IML), unscrewing moulds as well as moulds for service caps with automatic hinge closing system, in single-component and bi-component injection moulding processes. All customer moulds are commissioned and validated in-house on own high-performance machines, so that a production-ready handover takes place.

Webseite Firma Rouxel Mold:

https://www.rouxel-mold.com